Today we’d like to introduce you to Jeremiah O’Neill and Rens Hayes IV.

Prior to Hayes & O’Neill, the two principals worked for one of the largest structural engineering firms in Boston, Massachusetts, where they had the opportunity to work with some of the most technically advanced and well respected engineers and architects. During this time, they managed projects up and down the east coast, consisting of millions of square feet, and ranging from 1-story long span structures to 60-story hi-rise towers.

Jeremiah proved to be among the most technically advanced engineers, managing several hi-rise towers simultaneously and solving some of the most challenging engineering puzzles. Where he separates himself from the top engineers, is his ability to translate that engineering expertise into practical solutions. Not only can he translate, but communicates in a manner that non-engineers can understand leaving architects and developers with the comfort they are making the right decisions. Rens grew up in a structural steel and miscellaneous metals company Rens Welding and Fabricating, Inc. This hands on experience gives him an edge in identifying practical solutions for our customers. He has a knack for approaching building challenges from multiple perspectives and strives to understand the point of view of each party involved. This leads to a cohesive project team where each party understands the why and allows the best solution to win.

As colleagues, we recognized compatibility in each other’s core values, self-motivation and ability to communicate – key attributes to success in a partnership and in business. With a thriving development sector in the greater Boston area, we seized the opportunity to create a structural engineering firm that provides an impact well beyond engineering in every development we are involved with. We have built a core group of team members that echoes these same core values and reinforces the strength of this company. This core group provides the building blocks that our future growth will spur from.

Has it been a smooth road?

We started with a well-thought out business process with the goal of providing a road map to servicing a project as a consulting structural engineer at H&O. This invites our team to our own perspective on servicing each project type and helps to maintain a consistent end product. This provides the roadmap for the entry-level engineer to find early success and also allows the experienced engineer to become seamlessly integrated into H&O culture. It is our vision that these processes will be ever evolving, and will serve as the core document that can allow our company grows indefinitely while remaining true to our company’s core values. It has proven a challenge to build an index of processes that are scalable as our team grows, however we understand the importance of getting this implementation right and try to make the conscious effort to spend the time now and get this right.

Structural engineering services are unfortunately often seen as a commodity, where a developer or architect will jump at the lowest design fee under the assumption that they are saving a couple bucks. Unfortunately, the old adage ‘you get what you pay for’ often applies here….where an engineer can save you a couple bucks up front on their design fee, the same engineer can cost you many times more in additional construction costs. We have seen this exact scenario play out time and time again. It is our challenge to convey this to an owner and developer up front, and get them to buy into the expertise we bring to the table to provide the most efficient and cost effective design possible. The question is, would you spend $10k up front, to save $100k on the back end? Of course you would.

So let’s switch gears a bit and go into the Hayes & O’Neill Structural Engineering story. Tell us more about the business.

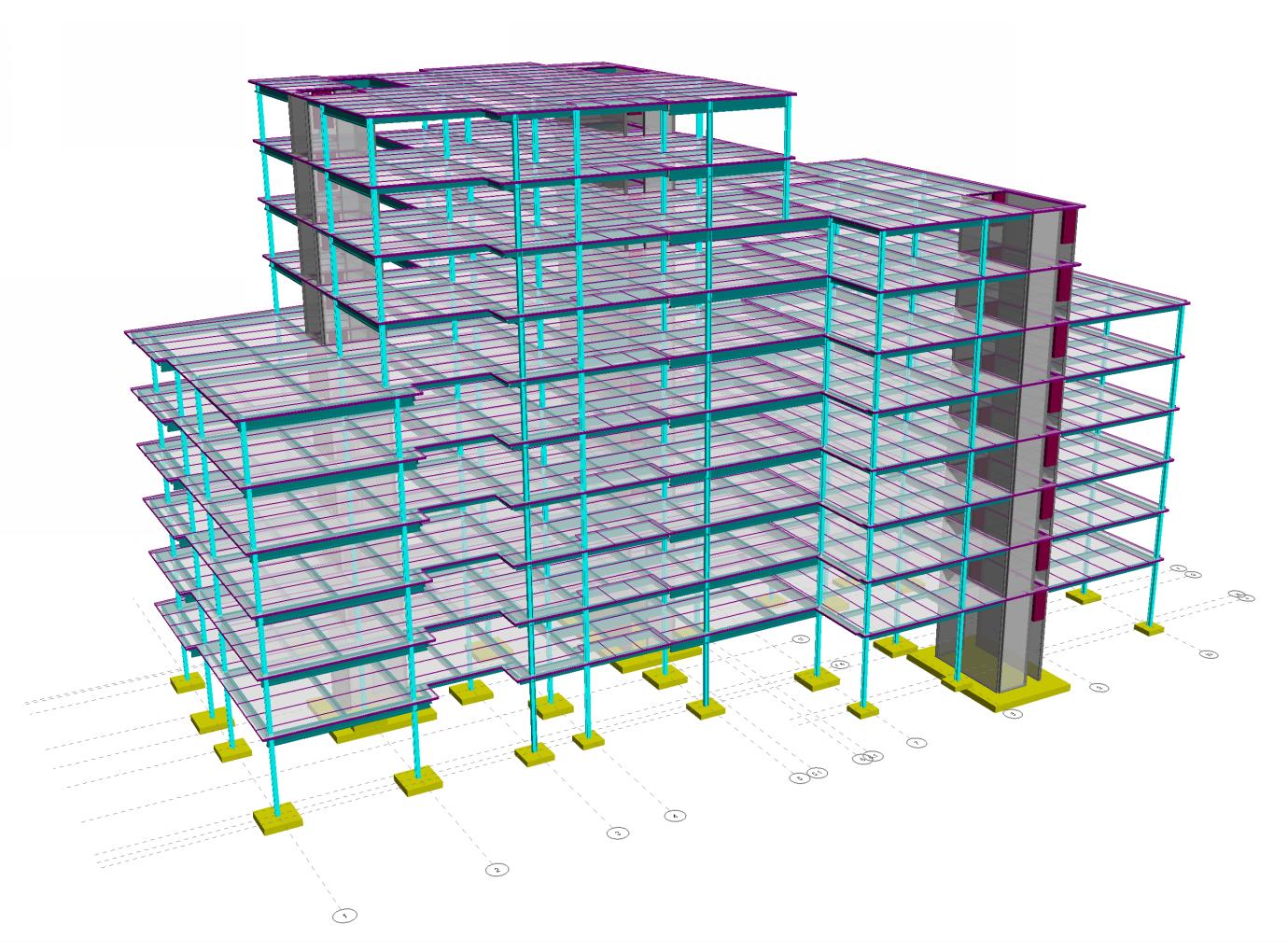

Hayes & O’Neill strives to be considered a value-add team member to all projects and developments. The vision for this firm is to take the technical engineering expertise needed to tackle the most complicated engineering puzzles and blend it with a practical construction know-how to ultimately provide a finished design that respects both architectural intent, constructability concerns, and project budgets. Our firm has embraced 3D modeling as an effective tool to better collaborate with the design team (architects, mechanical engineers, etc.) and a means to provide a better coordinated end product. All of our projects are 3D modeled in Autodesk Revit and all of our designs are modeled in 3D analysis software’s.

When you hire H&O, you get much more than structural engineering services. You gain business partners and well-informed consultants to your development team. Our engineering and construction experiences allow us to anticipate typically unforeseen challenges and communicate their impacts early in the design process. This leads to an efficient design process that accelerates the design schedule without sacrificing quality of the design drawings.

We pride ourselves in our team’s ability to communicate effectively and to provide timely responses; we are a reliable and responsive team member. Ever attempt to contact your structural engineer and fail to get a timely response? Not with H&O. We commit to providing seamless communication so that you’re not wondering when you might hear from us. We have the best team in the business.

How do you think the industry will change over the next decade?

Advancements in 3D modeling and highly coordinated upfront design is where we see a large focus these days. These technologies have advanced tremendously in the past 10 years; at their first introduction they were seen as cumbersome and were only used by industry specialists. We are now seeing that everyone, not just specialists, are engaging in 3D models, and it is proving to be an incredible tool for coordinating complex geometric and identifying possible construction issues. Most construction conflicts can be detected during design and corrected or addressed before a single dollar is lost on construction delays and field fixes. We do not see any down sides to 3D modeling and therefore a huge proponents of its use.

Contact Info:

- Address: 51 Melcher St

Boston, MA 02210 - Website: www.hayesoneill.com

- Phone: 617-938-3349

- Email: info@hayesoneill.com

- Instagram: https://www.instagram.com/hayes_oneill

- Facebook: https://www.facebook.com/HayesONeill/

- Twitter: https://twitter.com/hayes_oneill

Getting in touch: BostonVoyager is built on recommendations from the community; it’s how we uncover hidden gems, so if you know someone who deserves recognition please let us know here.